25 ton bridge crane for sale

25 ton bridge crane for sale

Bridge crane, also called lifting equipment, which can vertical lift and horizon handling goods at a certain range. With the development of modern technology, more factories not only chase the quality of goods, but also care about high productivity of their production machine. The overhead crane has been a necessary kit for building trades or other manufacture industry. Choosing a suitable crane, a large sum of spending can be saved, and the warehouse space can also be utilized appropriately. As a kind of bridge crane, 25 ton bridge crane commonly is regarded as a heavy duty crane with big lifting capacity. 25 ton overhead crane is widely used in warehouse, factory and another working environment.

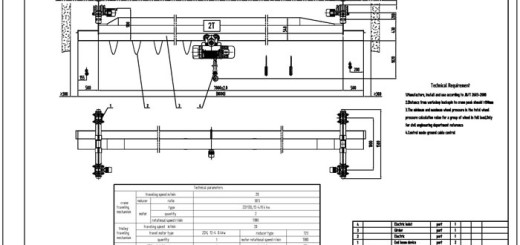

25 ton bridge crane parameters

Lifting capacity :5-320t

Span Length: 10.5~31.5m

Lifting Height: 6~18m

Working Class: A5, A6

Ambient Temperature: -20~40℃

QD type double girder overhead crane with hook parameters

Lifting capacity :5-320t

Span Length: 10.5~31.5m

Lifting Height: 6~18m

Working Class: A5, A6

Ambient Temperature: -20~40℃

QD type double girder overhead crane parameters

Lifting capacity :5-320t

Span Length: 10.5~31.5m

Lifting Height: 6~18m

Working Class: A5, A6

Ambient Temperature: -20~40℃

QE 25t Dual-trolley Overhead Crane parameters

Lifting Capacity: 3~500t

Span Length: 6~40m

Lifting Height: 3~60m

Lifting Speed: 0.1-13m/min

Working Class: A5 A6

QL type overhead crane with carrier-beam parameters

Lifting Capacity: 1~350t

Span Length: 6~45m

Lifting Height: 3~60m

Lifting Speed: 7.8-15.5m/min

Crane Speed: 20-30m/min

Working Class: A3-A7

QB type explosion proof overhead crane parameters

Lifting Capacity: 5~75t

Span Length: 10.5~31.5m

Lifting Height: 6~18m

Lifting Speed: 3-5m/min

Crane Speed: 20m/min

Working Class: A4

Explosion-proof Grade:ExdⅡBT4、ExdⅡCT4

Popular choice for Dongqi Crane’s 25 ton bridge crane

During over 70 years development, Dongqi Crane Company has became a powerful manufacturer and leading supplier in overhead crane industry. With the strong technology ability and rich experience, we can guarantee that every lifting machine or every component in crane, which produced by us can all accordance with the international standard. We can provide fully tested service for all our customers. So far, our bridge crane equipment has been exported into over 30 countries and region, including USA, Canada, Australia, India, Russia, and Africa and so on. At the same time, we won the highly thinking among our customers, being the first choice for them.

Related lifting machine of 25 ton bridge crane

There are many types of overhead crane, and everyone has its special features. Such as, compared with top running overhead crane the under hung overhead crane adapt in the factory with limited height. While the single girder bridge crane is more suitable to lift the goods with light weight, because of the small lifting capacity. Taking several special environments into consideration, like metallurgy, hydro power station or somewhere hazardous. We also can provide the explosion-proof overhead crane or the foundry overhead crane. Besides, according to different requirements of our customer, we are able to offer custom service. We will try our best to meet every demands of every customer.

Smart features of 25 ton bridge crane

- Profound appearance, strong steel

- Reasonable design, steady structure

- Advanced technology, limited speed

- Low clearance, light dead weight

- Start and stop smoothly

- Perfect quality, thought after-sale service

- Low noise, superior safety

- Environment- friendly

- Competitive price

How to extend working life of wire rope in Dongqi Crane’s 25 ton overhead crane

As one of crucial parts in any overhead crane, wire rope plays an important role during the use of materials lifting machines. However, due to frequent using, the wire rope is more prone to damage, then how to extend the service life of wire rope efficiently, what measures should you take?

After many years practice, we conclude several valid steps to lengthen the working life of overhead crane’s working life.

- Wire rope of tackle block comes out of groove

Before, wire rope of tackle block below hook comes out of groove frequently; this situation can be solved easily by resetting when nothing serious. However, once the wire rope move into the gap between two pulley blocks, it’s only under the condition that two or more persons work together hitting it fiercely with sledge hammer can restore the wire rope. However, it still is a bad method, because of the huge damage it creates on the wire rope. What is worse, once the wire rope comes out of the groove a time, this situation will happen more frequently, every work team will deal with this kind of trouble three times at least.

After analyses the reason carefully, we found that the round steel is too thin to fix the position of tackle block, as well as the diameter of the round steel is only 25mm, not only without enough intensity, but due to its bending deformation, leading to the big gap between the back plate and pulley blocks, that is why the wire rope will comes out of the groove more times.

Finally, aimed at the defect, we improve the diameter of back plate from 25mm to 40mm, and adjust the space between the back plate and tackle block from 10 ram to 5 ram, this strong and rigid back plate ensure the certain freedom of wire rope, at the same time, it also suit for the technology requirements.

2. The transform of suspension girder

Due to all several shapes of materials stocked in warehouse, the hook always works in the state of slope; this is particular true when more cargoes enter into factory. On that moment, closed wire rope will rub the three broadside of steel plate on suspension girder, leaving some serious abrasion in the middle of wire rope. After this takes place a few times, the wire rope will broke stand and even be scrapped in a short time. And also make certain friction on hanging beam.

The moment we find the reason, our professional experts’ team will research some new ways to avoid this phenomenal show up again. During more time practice and test, we find a better way. First, we raise the intensity of hanging beam, and add the thickness of plate steel from 10 ram to 14 ram, as well as the width from 250 ram original to 305 ram, length from 850 ram to 950 ram. Second, equipped two pulleys with the scale of 60mm*250mm on these three side, which between the hanging beam and the wire rope.