5 ton bridge crane for sale

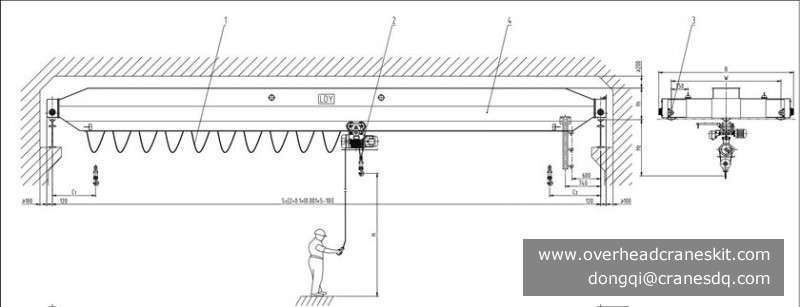

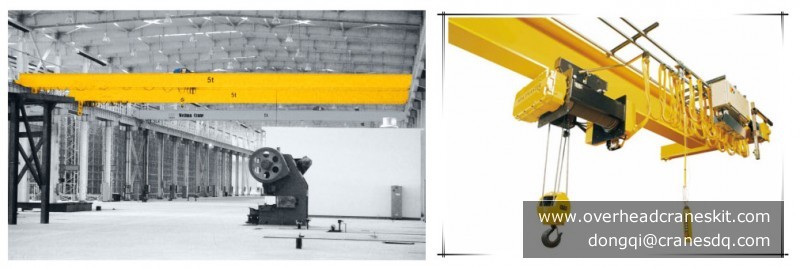

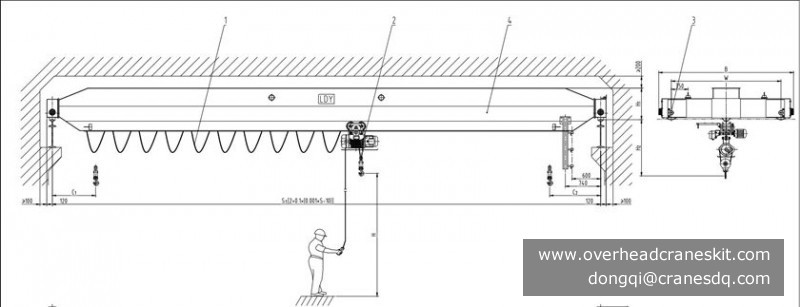

As a type of small and light overhead crane, 5 ton bridge crane usually is used in warehouse, factory and store shop to lift, move or transport all kinds of materials. The key feature of 5 ton bridge crane is its compact structure, which makes the overhead crane handle easily, and every part of overhead crane can work together very well. Best meet the need of high safety and productivity in modern warehouse. Therefore, 5 ton bridge crane is adjustable, and can fit various different working environments.

Smart features of 5 ton bridge crane

1. Portable and easy-to-use design

2. Compact and outstanding structure

3. Easily manipulate and maintenance

4. Advanced technology, high quality

5. Adjustable and movable

6. Strong rigidity and stable operation

7. Complete and reliable safety

8. Big lifting capacity and limited speed.

9. Specific guidance

10. Thoughtful after-sale service

11. Smoothly starting and stopping

Advanced Technology Used On 5 Ton Bridge Crane

- High and strict standard. Everyour 5 ton bridge crane is produced on the basis of international standard, such as the DIN, FEM, and ISO. Besides, our 5 ton bridge crane also passed a series of quality certificates, as well as many tests will be provided before purchasing, these measures makes our customers buy happily and reliably.

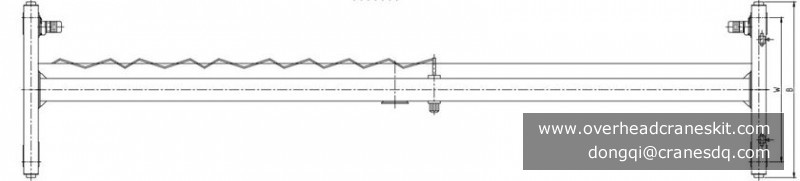

- Lightweight design brings lighter lifting equipment. Using the advanced technology, our new 5 ton bridge crane will create the lowest both in height and dead weight with about 25% and 30% decrease rate.

- Compact structure leads to the minimumspending in the construction of factory.

- Modular design takes shape rich product assortment and short delivery periods.

- High safety formed by many safe protection devices. Such as the monitor system in the overload limiter to avoid operator working condition timely and precisely. The switch limiter willcut down the electric automatically to alarm the hazardous situation.

- High quality components. Adaptingmany well performance components in every Dongqi Crane’s 5 ton overhead crane to add another safeguard for the material lifting equipments. Just like the exported wire rope and motor from German.

The important role of overhead crane’s working duty

Though the working duty of overhead crane, we will get this clear evidence easily to examine safety, analyses accident and determine whether some components reach the standard or scarp or not, which is an important stuff for figuring out safety level of an overhead crane. General speaking, different kinds of material lifting machine enjoy a diversified physical standard in the aspect of working duty, safety level and scarp rules.

However, with amazing design and responsible attitude, Dongqi Crane always is your best choice for all kinds of overhead cranes.

First, the utilization rank of an overhead crane mainly refers to the using degree in its all service life. What’s more, one kind of overhead crane has 10 classes on different number of operation cycle in total from U0 to U9. The load-up condition on an overhead crane show the distinct weight of goods that one crane equipment need to lift, which can be divided into four grades from light to extra heavy. When taking consider of utilization level and load-up condition together, we can get a quite precise class about an overhead crane’s working duty from A1 to A8.

Second, like the utilization degree, according to the gross hours of working state when an overhead crane is designed during its whole service life, how busy of one overhead crane also fall into 10 levels from T0 to T9. At the same time, the load-up condition also presents the load degree, which also falls into four levels from light to extra heavy. in the light of diagonals principle, the working duty fall into 8 classes from M1 to M8 on the basis of analyses both the utilization and load-up condition.

Detailed requirements of examination on bridge crane

1. You should text the fixed position of the traveling rail. To make sure that both fixed device and traveling rail are in good state.

2. Ensure the height limiter, stroke limiter; buffer and emergency power off of overhead crane are all in normal.

3. Examine the hook or steel wire rope, and to avoid any risk caused by them.

How to maintenance the bridge crane

1. Kept all components clean.

2. Examine or adjust speed reducer timely

3. Fasten and supplement bolt on the point of connection.

4. make sure all the safety device are in good state

5. Deal with poor performance steel wire rope and roller

6. Ensure all the place or point be oiled well.

Popular choice for Dongqi Crane’s 5 ton bridge crane

Dongqi Crane Company is a mature and qualified overhead crane manufacturer with more than 700 clients and 6 factories. During a half-century development, Dongqi Crane Company has accumulated rich experience and professional engineers. We always adhere to the principle of “customer first, technology ahead”. No matter what material handling solution you need, Dongqi Crane can meet them with advanced technology and responsible attitude. Every component and crane machine is produced on the basis of international standard. We are strictly treated the quality of every overhead crane, and the fully test will be provided before purchase. Relying on these, we won a lot of customers both home and abroad. Dongqi Crane Company will be the best and right choice for you.

There are various overhead cranes we can provide for you. Such as the overhead crane, overhead bridge crane, gantry crane, jib crane and series of hoist equipment. Aimed at different hung ways, we have under hung overhead crane suitable for the space is limited in the factory. On the contrary, if a factory has high bedroom, a top running bridge crane may be the best choice. Besides, we also offer the single girder bridge crane and double girder bridge crane. Considering the different working environment, we are able to manufacture the special lifting kits to adapt in some hazardous environment. Such as the explosion-proof overhead crane and the foundry overhead crane and so on. Additional, we are capable to custom kinds of specific cranes to meet all your requirements.

HD type european standard overhead crane parameters

Lifting Capacity: 3.2~16t

Span Length: 7.5~28.5m

Lifting Height: 6~12m

Lifting Speed: 0.66/4-1.6/10m/min

Trolley Speed: 2-20m/min

Working Class: A5

Ambient Temperature: -20~40℃

LDP type partial hoist overhead crane parameters

Lifting Capacity: 3~10t

Span Length: 7.5~22.5m

Lifting Height: 3~30m

Working Class: A3 A4

Ambient Temperature: -25~40℃

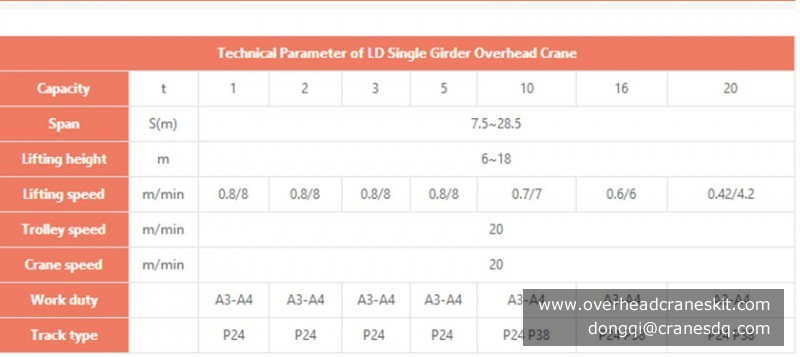

LDtype single girder electric hoist crane parameters

Lifting Capacity: 1-20t

Span Length: 7.5-28.5m

Lifting Height: 6-18m

Lifting Speed: Single/Double/Variable Speed

Working Class: A3, A4

Ambient Temperature: -20-40℃

LDZ Grab Overhead Crane parameters

Lifting Capacity: 2~10t

Span Length: 4.5~28.5m

Lifting Height: 6~18m

Lifting Speed:16m/min

Crane Speed: 20-30m/mim

Working Class: A4

Ambient Temperature: -20~40℃

QD type double girder overhead crane with hook parameters

Lifting capacity :5-320t

Span Length: 10.5~31.5m

Lifting Height: 6~18m

Working Class: A5, A6

Ambient Temperature: -20~40℃

QZ type grab bucket overhead crane parameters

Lifting Capacity: 5~20t

Span Length: 10.5~31.5m

Lifting Height: 6~18m

Working Class: A5, A6

Ambient Temperature: -20~40℃