Overhead Crane Solution Saves Your Space

Paraguay EPS Sandwich Panel Factory Crane project Case Study

Overhead Cranes also named Bridge Cranes or Electrical Overhead Traveling (EOT) Cranes is kind of industrial lifting equipment, which is widely used in various industrial applications for material handling to improve working efficiency and safety. According to the material handling purpose and structure, the overhead crane can mainly be classified into the following type, Low Headroom Single Girder Overhead Crane QDY Ladle Overhead Crane, Single Girder Suspension overhead Crane, Double Girder Electric Hoist Crane, Explosion Proof Bridge Crane, Explosion-proof Single Girder Overhead Crane, Electromagnetic Overhead Crane, Single Girder Electric Hoist Crane up, Overhead Crane With Hook, Grab Bucket Overhead Crane, Insulation Overhead Crane and Double Trolley Overhead Crane, etc.

Among the various overhead cranes, how to choose the optimal one for your applications? It depends on your factory conditions and material handling requirements. What if your working area is limited, you need relatively larger working space for material handling? How to solve the trouble? Now let’s see how DQCRANES solves the problem and see the Paraguay EPS sandwich panel factory crane project case study.

Customer’s company profile

The Paraguay client is a manufacturer of thermal sandwich panels. They have several thermal sandwich panel production lines, which has certain influence in their local market.

Thermal sandwich panels from the Paraguay client Of DQCRANES

Lifting requirements

During the sandwich panel production, they need to move coils of steel sheet for stocking and for placing them in a continuous production line for EPS sandwich panel. Here comes the question: The factory has been built up within the wall with the height around 1.2 m which limits the working area of material handling. In order make the most of the working space, the client requires that the bucket should be set up closely against the wall. How to realize these requirements? See our solution diagram below:

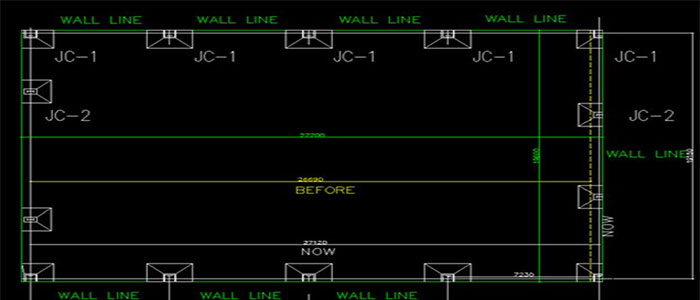

Crane bucket foundation drawing

Material handling solution

Based on the working conditions and lifting requirements, DQCRANES recommended the Paraguay client the 10 ton single girder overhead crane, with a special designed bucket, at the corners the foundations of which are narrowed down to 1/4 of the normal size and special materials and additional bolts are used to ensure the stability and safety (Seen the designing drawing above).

The bucket and bolts for the single girder overhead crane

The single girder overhead crane can help the client to lift and move the coil of steel plates and the specially designed foundation can largely save space for the crane. At same time, the safety and stability of the overhead crane is guaranteed. The lifting requirements of the client are perfectly satisfied.

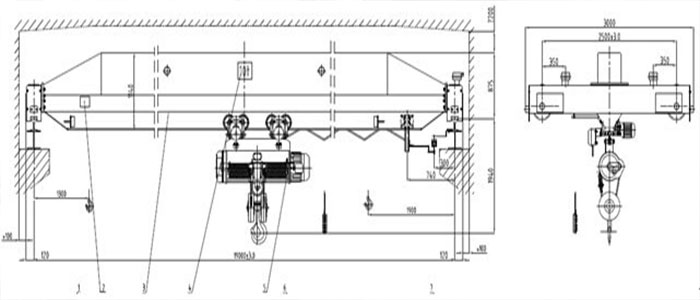

Single girder overhead crane drawing

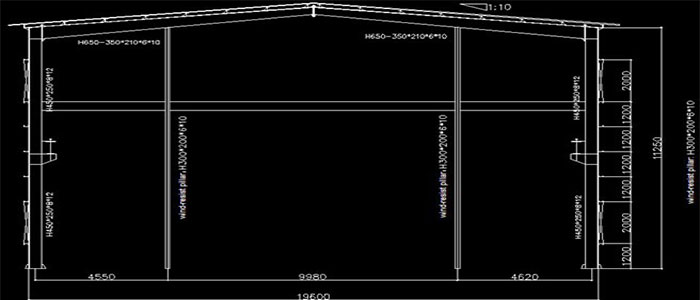

10 ton single girder overhead crane with steel structure workshop

After the confirming of the crane drawing, everything went well with the crane production, packaging and delivery and installation.

Packing picture of single girder overhead crane

Packing picture of single girder overhead crane

Overhead crane shipment picture

DQCRANES suggest customer choose the open top container due to irregular shape, since it’s easy for loading and unloading, and it is safe as well.

Delivery of the overhead crane

Customer’s installation site:

DQCRANES provide detailed installation instruction, including mechanism and electric, it’s easy for customer if they choose to install it by themselves. We can also provide installation guide by phone or email or other communication tools if customer request.

Overhead crane installed at the Paraguay factory

Conclusion

As for the crane project, the features of the material handling solutions are:

1)10 ton single girder overhead crane can fully meet the material handling requirement of the coils of steel plates which is cost effective.

2) The special designed crane bucket and foundation can largely save the working space which on the other hand improves the cost-effectiveness of the single girder overhead crane.

3) The safety and stability of the crane is guaranteed with low cost.

DQCRANES is always dedicated to provide optimal material handling solution for clients around world. No matter what kind of conditions you have and what kind of problem confronted, DQCRANES will find the most ideal one for you. DQCRANES is here to lift you up!

Dongqi overhead crane offering

LH Double Girder Electric Hoist Overhead Crane

|

The crane can lift loads from 5 to 63 ton, which is widely used in machinery fabrication, metallurgical plant auxiliary workshop, storage, stock ground, and power station, textile industry and food industry. |

LD Single Girder Electric Hoist Overhead Crane

|

It is a light small overhead crane with the capacity of 1to 32 tons, which is widely used in the factory, ware house, stockyard, etc. |

LX Single Girder Suspension Overhead Crane

|

The overhead crane is a small light lifting equipment, with the lifting capacity range from 1 to 10 tons, equipped with dual-speed electric hoist, which is widely used in the factory, warehouse, stockyard, etc. |

|

The hook overhead crane can be used to lift loads from 5 tons to 550 tons, which is widely used to upload and move of normal weight in the fixed crossing space and also can work with various special-purpose hoist in special operations. |

|

The grab bucket overhead crane has the lifting capacity around 5 to 25 tons together with the weight of the grab bucket, which is widely used in power station, storage, workshop, and port to load and unload scattered objects. |

QC Electromagnetic Overhead Crane

|

The overhead crane is used in metallurgy factory or outdoor place to load and transport electromagnetic black metal materials, such as, steel ingot, merchant steel and pig iron, etc. The lift capacity is from 5 to 32 tons. |

NLX European Style Underslung Crane

|

European underslung crane is one of the most economical material handling equipment. Underslung crane can handle material from 1 to 20 tons for you! |

European Style Double Girder Overhead Crane

|

European double girder overhead crane for 5 – 80 ton material handling. The overhead cranes realize all your expectation to material handling. Bet you want it! |

HD Electric Hoist Overhead Crane

|

Electric hoist overhead crane is designed with European design and unbeatable advantages for sale now. Sturdy quality. Good price. One year quality assurance. Full set of aftersales overhead crane service. |

LDP Low Headroom Single Girder Overhead Crane

|

They are designed for low height plant and factory, where the lifting room is limited but lifting height is high. The lifting capacity of the overhead crane is 1 to 32 tons whereas the lifting height is 6~20m. |

|

They are widely used in the smelting industry to convey, pour and charge the liquid hot metal in the process of smelting, and the lifting capacity of the ladle overhead crane is from 5 to 74 tons. |

QB Explosion Proof Overhead Crane

|

The overhead crane is designed for explosive gas atmospheres with explosion-proof electrical equipment. They can lift loads from 5 ton to 75 tons. |

LB Explosion-proof Single Girder Overhead Crane

|

The single girder overhead crane is also designed for explosion proof environment. The lifting capacity is from 1 ton to 20 tons. |

|

Electrolytic aluminum crane is designed for material handling in aluminum plant. The high safety electrolytic aluminum crane is multifunctional, ensuring your material handling efficiency. |

|

The overhead crane is used to handle electrolyse non-ferrous metals such as magnesium, aluminum. The lifting capacity is from 5 tons to 50 tons. |

QE Double Trolley Overhead Crane

|

The double trolley overhead crane is used to lift long and big loads with the capacity of ((2.5+2.5)~(200+200)t. |