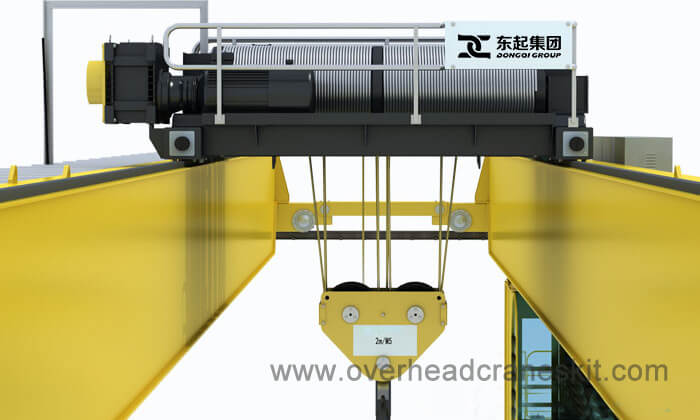

Industrial crane for sale

As the best solution, industrial crane can adapt various working environments including hazardous and poor conditions. In other world, industrial crane is ideal to improve the working efficiency and productivity. Due to high safety and large lifting capacity, the industrial overhead crane is widely used in workshop, warehouse, power station, metallurgical mills and other place.

Aimed at distinct working environment, we can design and manufacture kinds of industrial overhead crane. Such as the single girder overhead crane is suitable for lifting goods under 20 tons. However, compared with single girder bridge crane, double beam overhead crane own bigger lifting capacity, which can reach 500 tons. To apply for diverse factory headroom, we offer two suspend ways, the under hung overhead crane and the top running overhead crane. When the space of your warehouse is limited, a under running overhead crane may be the best choice, on the contrary, you’d better select the top running overhead crane.

Besides, on the basis of your detail and particular requirements, we are also able to custom perfect overhead cranes.

20t LH Double Girder Lifting Crane parameters

Lifting Capacity: 20t

Span Length: 10.5~31.5m

Lifting Height: 6~18m

Working Class: A4

Ambient Temperature: -20~40℃

100 ton overhead crane parameters

Lifting capacity: 100t

Span length: 10.5-31.5m

Lifting height: 6-20m

Working duty: A7

Ambient temperature : -10~50℃

LH Double Girder Lifting Crane parameters

Lifting Capacity: 5~32t

Span Length: 10.5~31.5m

Lifting Height: 6~18m

Working Class: A4

Ambient Temperature: -20~40℃

100 ton overhead crane from Dongqi Crane parameters

Lifting capacity: 100t

Span length: 10.5-31.5m

Lifting height: 6-20m

Working duty: A5, A6

Ambient temperature: -20~40℃

QC type electromagnetic overhead crane parameters

Lifting Capacity: 15t

Span Length: 10.5~31.5m

Lifting Height: 6~80m

Lifting Speed: 7.8-15.5m/min

Crane Speed: 42-112m/min

Working Class: A6

QL type overhead crane with carrier-beam parameters

Lifting Capacity: 1~350t

Span Length: 6~45m

Lifting Height: 3~60m

Lifting Speed: 7.8-15.5m/min

Crane Speed: 20-30m/min

Working Class: A3-A7

Best choice for Dongqi Crane’s industrial crane

With 70 years development, Dongqi Crane Company has been the leader in overhead crane industry. We are qualified and capable to manufacture various kinds of lifting machine. Just like, bridge crane, gantry crane, jib crane or many types of hoists. With sales worldwide, service and repair centers nationwide, we provide thoughtful pre-sale and after-sale service. Guide by strict standard and prudent attitude, our professional experts can design, manufacture, and install every perfect overhead crane for you. At the same time, we can also provide several crane parts, hoists, repairs, training and recommended spare parts. As well as the fully test can also be offered before you buying. So far, our products has been exported into more than 30 countries and regions around the world including America, England, Africa , India, Australia and the middle east and so on. We also became the world choice for overhead crane.

Smart features of industrial crane

- Rigid and stable steel structure

- Reasonable design

- Outstanding appearance

- Light dead weight

- Low clearance

- Advanced technology and professional guide

- reliable quality and high performance

- Strong technology team

- Easy installation and maintenance

- Thoughtful pre-sale and after-sale service

- Competitive price

How to extend the working life of overhead crane effectively

Because manufacture an overhead crane costs too much, its maintenance becomes a hot question. Our professional engineer put forwards three important points about extend the working life of overhead crane effectively.

First, be strict with specification when uses a lifting machine.

Second, keeps periodic maintenance. According to related requirements of equipment usage profile to maintenance an overhead crane, which can eliminate or avoid potential risks and ensure kit works well. For example, several applicable measures should be taken in poor environment.

Third, requires reasonable maintenance. It mainly refers to under the help of advanced equipment or progressive testing methods to repair the overhead crane. Using a reasonable means and skilled technologist not only can reduce the rate of breakdown, but also save spending and extend crane’s service life.