Dongqi Hoist Type Overhead Crane, with 3-32T Capacity and A3-A6 Working Duty

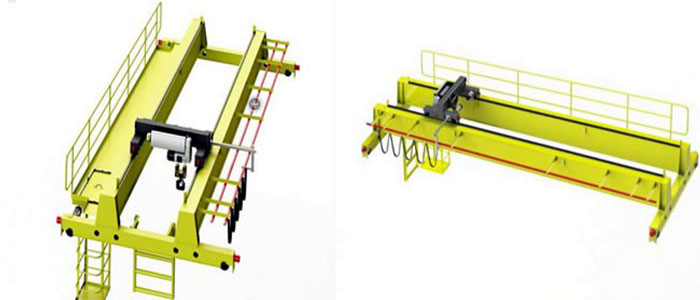

European FEM double girder overhead crane diagram

Key Specifications/Special Features

- Lifting capacity: 3-32 tons

- Span and lifting height: according to your demand

- Power source: according to your demand

- Double-beam overhead crane is a renewed product

- New designing reduces the weight of the steel structure and makes the crane more reasonable

- It is composed of bridge, trolley-traveling mechanism, crab and electrical appliances

- Lifting capacities are 3 to 32T, the span is 10 to 31m and working system is A5

- It has such features as tight dimensions, low building headroom, light dead and light wheel load

- They are applicable to be the transfer, assembly, check and repair as well as load and unload at mechanic processing workshop, subsidiary workshop of metallurgical mills, warehouses, goods yard and power station

- Two operating methods, namely, on floor and in the driver’s cabin, the cabin is divided into open and closed style

- Cabin can be installed on the left or right according to actual conditions

- Operator can enter the cabin from one side, rear or top, which depends on the different user’s requirements

- Safety:

- Overload protection

- Main lifting motor with thermal protection

- Hooks with latch

- Rubber buffers

- Protective earthing

- Crane switch and travel end switch

- Emergency switch can stop all movement when any danger happens

- Sub-assemblies characteristic are tested before assembly

- All cranes must be pre-assembled and tested before leaving factory and offer the certification of test

- Design and construction rules: all the standards which is required for the crane is the Chinese standard:

- Painting:

- Primer and finishing paint

- Customized colors are welcome

- Average thickness: about 100 microns