Crane Maintanence: Crane contactor introduction and common faults

Crane Contactor Introduction

Contactor is divided into AC contactor and DC contactor according to the voltage. It is applied to electric power, power distribution and electricity. Crane contactor is AC contactor.

Crane contactor working principle: after the contactor coil current, coil current creates a magnetic field, the magnetic field to produce electromagnetic static core gravitational pull move iron core, and drive the crane contactor action, normally closed contacts disconnect, normally open contact closure, the two are linked. When coil without power, electromagnetic suction disappears, armature in released under the action of the spring, make contact recovery, normally open contacts disconnect, normally closed contact closure.

Crane contactor open and close circuit by main contact and conduct control loop with by auxiliary contacts. The main contact is normally open contacts and auxiliary contacts often have two normally open contacts and normally closed contacts, small contactor is also often used as intermediate relay. Crane contactor contact that is made of silver tungsten alloy has good electrical conductivity and high temperature erosion resistance. Crane contactor action from power created through communication with iron core coil magnetic field, electromagnetic iron core is made up of two “mountain” glyph of silicon steel sheet pile into, one of the fixed core with one set of coil. The working voltage can be a variety of choices. In order to make the magnetic stability, short circuit ring is added on core of suction surface. Crane contactor reset through the spring after losing electricity. The other half is activity core, tectonic same as fixed iron core, used to drive the main contact and auxiliary contacts open and close.

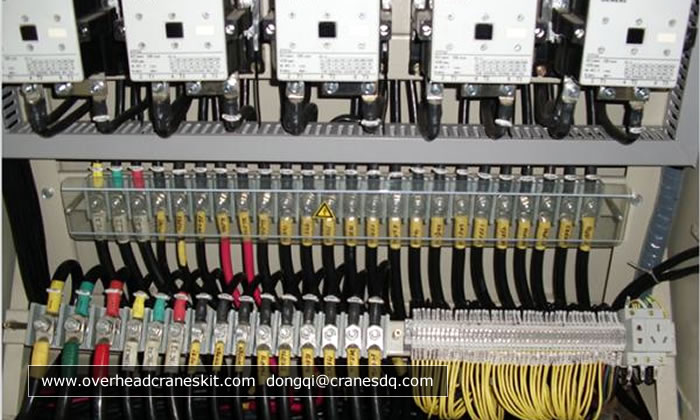

Crane contactor

Crane contactor common faults as following

- Fault 1: Don’t move or action is not reliable

- Fault 2: Don’t release or slow release

- Fault 3: Coil overheating or burning

- Fault 4: Electromagnet (ac) noise

- Fault 5: Contact welding

- Fault 6: An eight-hour working day system contact overheating or burning

- Fault 7: In a short period of time contact excessive wear

- Fault 8: Short circuit between phases

If you have any problem about crane, Dongqi crane can supply you professional technical service. Welcome to contact us.