1-20 ton Single Girder Electric Hoist Gantry Crane

Single Girder Electric Hoist Gantry Crane Overview

Single Girder Electric Hoist Gantry Crane is light type gantry crane take CD electric hoist or MD electric hoist as lifting mechanism, through lifting mechanism – electric hoist hook moves up and down, trolley moves left and right and the crane back and forth traveling combined forming the stereo work space, to achieve movement, flip and other operations of the lifting objects.

Lifting capacity: 1-20 ton

Crane span: 5~35m

Lifting height: 6m, 9m, 12m, 15m, 18m

Voltage: 220~480V

Single Girder Electric Hoist Gantry Crane Types

Hoist gantry crane is single girder gantry crane, can be divided into L-type hoist gantry crane and A-type hoist gantry crane according to the leg shape. Light weight, simple mechanism, easy to operation, widely used in docks, freight yard, warehouses, construction sites and other conditions.

Single girder hoist gantry crane types

Hoist gantry crane working-level is A4, generally used for outdoor work, the crane and trolley lifting mechanism both set with rain cover.

Single Girder Electric Hoist Gantry Crane Features

Hoist gantry crane mainly consists of gantry frame structure, crane traveling mechanism, electric hoists lifting mechanism and electrical control system.

Gantry Frame Structure

Gantry frame mainly consists of: main beam, ground beam, legs, ladder platform, driver’s cabin and other components.

Main beam is the main bearing carrier of hoist crane, and also the track of hanging electric hoist. Main beam made by Q235 or Q345 steel rolling into U-shaped groove, oblique cover plate, ribs and I-beam welding into plain girder or with steel plate welding into box girder. Electric hoist trolley runs on the I-beam flange. On both sides of main girder span position designed with saddle seat connected the legs, and there is a rectangular steel connecting flange. Both ends of the main beam has buffer to ensure that trolley running on the main beam safely.

Ground beam is basis of bearing the main beam and load, and it is also the tie of main beam and traveling mechanism, is one of the main bearing member of crane metal structure, mainly made by U-shaped groove and steel welding or steel plate welding into box-shape structure, with compact structure, good rigidity, good appearance, good welding performance and other characteristics. The end of the ground beam is provided with buffer.

Leg is isosceles trapezoid box or right-angle trapezoidal cross-section column welded by Q235 or Q345 steel plate, column up and down welding with different width flange. The upper flange is wide; while the lower flange is narrow, to increase the strength, rigidity and stability of the gantry frame. When the crane span is more than 30 meters, it will be designed with a pair of flexible legs to improve crane traveling.

The main beam and the saddle seat symmetrical arranged on both side of the main beam fastened two flanges by bolts, and make the distance between the two legs with narrow above and wide below, that forms “A”-shaped structure, improve the stability of the crane. Steel flange between leg and the ground beam connected by bolts. This structure is simple, easy to install, easy to transport and storage.

Single girder electric hoist gantry crane

Gantry Crane Traveling Mechanism

Crane traveling mechanism mainly consists of: running motor, running gear, wheel set and other components. It is also divided into different structural forms-A type and B type depending on different lifting tonnage. The whole crane driving set is with simple structure, low noise, generously appearance, safe and reliable operation, easy installation and maintenance.

Electrical Control

Including three modes: Direct control, string resistance startup, frequency control.

Power supply: safety slide wire, cables and cable drum, soft cable.

Operation mode

Ground operation: press the button on the handle to control all crane mechanism movement.

Remote control: industrial remote to control the appropriate mechanism action.

Cabin Operation: Cabin button, master, cam controller or linkage control crane appropriate mechanism action.

Electrical Protection Systems

- Short circuit protection

The total power circuit set up automatic air switches, as the crane short-circuits protection; control loop setting small capacity automatic air switch as short-circuit protection. - No-voltage protection

Circuit structure has function of no-voltage protection, after power failure must press the start button to restore power and re-run the crane, eliminate the possibility of the crane power self-running. - Emergency power-off switch

Crane set with red mushroom type rotary reset emergency power off switch for emergency situations quickly cut off the crane main power and control circuit. Emergency power off switch mounted in place to facilitate personnel operations. - Overload Limiter

When the capacity reaches 90% of rated load, overload limiter issued suggestive alarm signal, when the capacity reaches 110% of rated load, overload limiter immediately cut off the power supply and issued prohibitions alarm signal. Overload limiter sensor with moistureproof seismic characteristics, sensor and control box connected as a whole, reducing the sensor signal interference. - Travel limit

Lifting mechanism is provided with rising and falling off fire stopper, as the lifting mechanism lifting range limit switch.

Crane traveling mechanism is provided with operating limit limiter. It consists of travel limit switch and safety stop, travel limit switch is mounted on the crane, crane safety stop mounted on the place not affect crane operation, to ensure that the crane operation within safety range. - Zero and chain protection

Driver’s cabin operating crane with zero protection and cabin door switch chain protection. Zero protection prevents the occurrence of motor functioning automatically when power is restored after a power failure, to prevent accidents. Cabin door switch chain protection avoided crane suddenly runs leading to persons or objects falling from the door because of the safety door is not closed. - Off phase, wrong phase, overvoltage, low-voltage protection

Crane circuit system integrated protection with off phase, wrong phase, over voltage and low-voltage protection, and will automatically cut off crane total power to prevent personal injury and equipment damage when the above four cases occurred. - Ground Connection

Crane metal body and all electrical equipment metal casing, tube seat, the low voltage side of the transformer are all equipped with reliable ground connection, the total grounding resistance ≤4Ω, allowing the use of the crane rail as the ground wire.

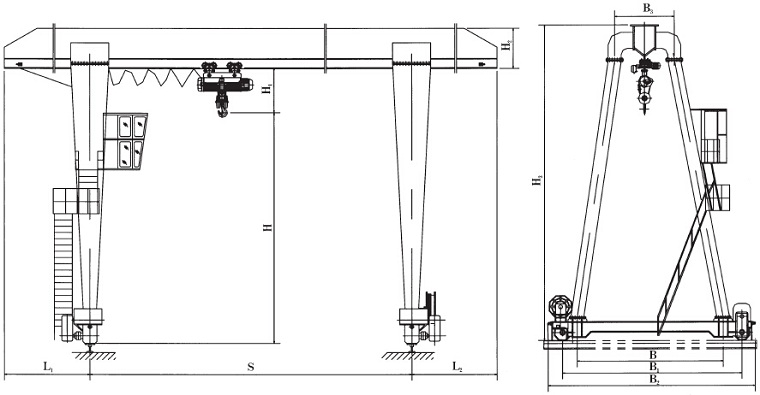

A-type Electric Hoist Gantry Crane Drawing

Single girder hoist gantry crane drawing