1-500 ton A-type Double Girder Gantry Crane

Double girder gantry crane

A-type Double Girder Gantry Crane Overview

A-type Gantry Crane is A-type double girder gantry crane; consists of A-type gantry frame steel structure, trolley, crane traveling mechanism, electrical system and other main components. Outdoor operation gantry crane also equipped with rail clamp, weight restriction device, limit device of each mechanism, as well as various safety devices in accordance with prescribed safety procedures of cranes. Sometimes the crane also equipped with rail clamp device, anchor device, anemometer, corrective devices, etc. as required.

A-type Gantry Crane-double girder gantry crane with hook are used for handling and lifting materials in open storage, stock ground, railway freight station, ports and so on. It can also carry out some special operations by equipped with various special lifting tools.

Its load handling device is hook, grab or electromagnetic chunk (lifting magnet), or simultaneously use with the two or three. There have three forms of gantry frame structure: double cantilever, single cantilever and non-cantilever. When its load handling device is hook, the crane working level is A2 ~ A6, when it is grab or electromagnetic chuck, the crane working level is A4 ~ A7.

Lifting Capacity: 1-500 ton

Lifting Height: 6m, 9m, 12m, 15m, 18m

Crane Span: 5~35m

Working Class: A5, A6, A7

Ambient Temperature: -20~40℃

A-type Double Girder Gantry Crane Features

Main Structure and components

A-type Gantry crane consists of gantry frame steel structure, trolley, crane traveling mechanism, electrical system and other major components.

To facilitate transport, loading, unloading and installation on site, on the main components set up lugs, hanging holes, etc. used for lifting. The intensity and location of these lugs and hanging holes fully consider lifting safety and convenience.

A type double girder gantry crane

Gantry frame steel structure

Gantry crane steel structure mainly consists of the main beam, supporting legs (when large span using of one rigid leg and one flexible leg), end beams, saddle (no saddle when no cantilever), trolley traveling track, bottom cross beam and other components. Connect the main beam, end beam, legs, saddle, bottom cross beam together by high strength bolts.

Main Girder

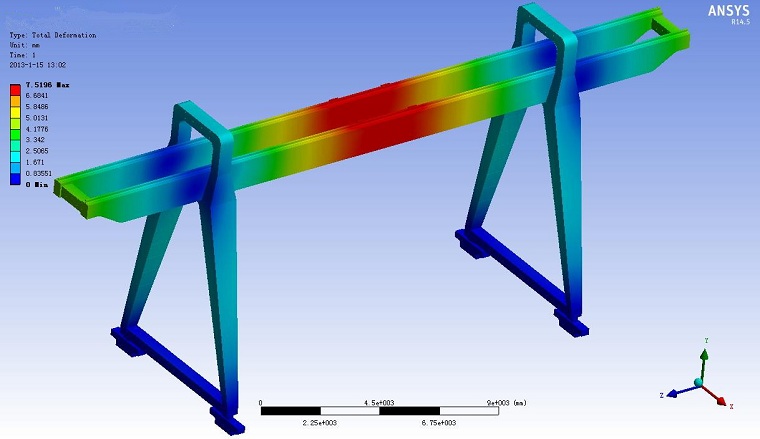

Main girder use welding box type or truss type. Main girder cross section uses the ANSYS finite element calculation method for systematic analysis and calculation.

Main beam camber is (1 ~ 1.4) S / 1000, and the maximum camber position is controlled in range 1/10 of the span middle. The main beam force piece material is Q235 or Q345 (similar to Fe37 or Fe52), minimum plate thickness is more than 6mm.

A type double girder gantry crane

Landing Leg

Adopt welded box-shaped, leg consists of the upper flange, lower flange, steel plate or welded steel support. Upper flange is large and lower flange is small, so that the legs become upper big and lower small variable cross-section structure, can effective bearing loads of vertical and horizontal directions.

Driver’s Cabin

Driver’s cabin is the workplace that the operator manipulate crane, its structural type design has taken into consideration the needs of a variety of functions, durable, safe and reliable, and also considered a good view, comfortable and beautiful, to make the driver feel comfortable during operation.

In order to ensure the operator vision, before the top, before the bottom side wall and rear wall of the driver’s cabin are fitted with tempered glass, driver’s seat with a maximum elevation at 55 ~ 60 °, the maximum angle 70 ~ 75 °, the driver fixed maximum positive perspective 120 °, seat rotating angle of the front can up to 270 ° of viewing range.

Driver’s cabin structure welded of steel plate and steel, mounted on a bracket below the main beam. Its connection should be solid and reliable, with sufficient strength and rigidity.

Various settings arranged in driver’s cabin, give full consideration to the driver of convenient maintenance, easy manipulation, unobstructed walking and active space. Guaranteed the driver can quickly and safely withdraw in accident situations.

Platform, Ladder

Where it is need operation, inspection, repairing there equipped with safe and reliable ladder, platform and walkway, and it is with enough work space. Platform walkway equipped with railings, its height is 1050mm, anywhere of the railing can afford 1kN load from any direction without causing plastic deformation. Consider non-slip safety measures on platform walkway.

Trolley

The trolley is mainly composed of one or two sets (main and auxiliary lifting) hoisting mechanism, trolley traveling mechanism and trolley frame.

Hoisting Mechanism

Hoisting mechanism mainly consists of: reel, lifting motor, lifting reducer, brake, wire rope and hook (or grab, electromagnetic chuck) and other components.

Lifting mechanism operating principle: Motor acting through the gear shifting speed, and then driving drum through drum coupling, finish hook hoisting through wire rope winding system. After power off, the brake closed, hook stop hoisting and keep the lifting object still in the air.

Lifting mechanism including main and auxiliary lifting mechanisms, arranged in the same trolley frame, each set with separate driving device, main and auxiliary lifting mechanisms not only can finish the lifting and handling independently, but also can be coordinated to complete the work of turning over object.

Each component of lifting mechanism with compact layout, easy maintenance, ensure safe and reliable.

Trolley Frame

Trolley frame is steel plate welded combination structure, with sufficient strength and rigidity to ensure normal work of each agency after trolley frame deformation under load. Outdoor work trolley uses sealed form rain cover, the rain cover with daylighting measures.

Trolley traveling mechanism

It consists of traveling motor, running reducer, wheel sets and other components. The trolley equipped with stopper device, rail clearer, buffer, traveling limit and other safety devices.

Trolley traveling mechanism operating principle: After power on, the brake open, motor acting output power, shifting speed by reducer, driving wheels via drive shafts and couplings, then complete crane forward and backward movement, after power failure, the brake closed, trolley stop traveling.

Crane Traveling Mechanism

Crane traveling mechanism adopts respectively drive form. It consists of motor, brake, reducer, wheel sets, drive shafts, couplings and other components.

Crane traveling mechanism operating principle: After power on, the brake open, motor acting output power, shifting speed by reducer, driving wheels via drive shafts and couplings, then complete crane forward and backward movement, after a power failure, the brake closed, crane stop traveling.

Crane traveling wheels are four or eight (will be more in special circumstances), wheel and the angle bearing box with roller bearing (or 45ºsplit structure bearing box) mounted on the balance wheel set after assembly.

Gantry crane Operation

All agencies operated by driver’s cabin, control lifting, crane and trolley traveling. Cabin fitted with an emergency stop button; press this button for an emergency cut off the whole crane power supply.

Crane with an emergency power-off switch, in case of emergency, you can cut off the crane total power, the switch is located in the power distribution cabinet.

Motor is equipped with fully functional protection device, overcurrent, short circuit fault of the motor can be effectively protected.

Crane has zero protection, when the agency prepared to operate or power is restored, the controller must first be placed in the zero position, then press the start button, the motors of all agencies can start.

With warning bell, work prompted by a foot switch.

Overload load limiters: Crane with overload load limiters, when load reaches 90% of rated, the display device will automatically alarm; when the load reaches 105% of rated, the crane will automatically cut off the power supply of hoisting mechanism.

Rising limit position protection device: hook lifting mechanism with limit device, when hoisting to a limit position, automatically cut off the lifting power supply.

Stroke limiter: both sides of crane and trolley traveling mechanism are equipped with stroke limiter, it will automatically cut off power when crane and trolley traveling to the limit position, then they can traveling in the opposite direction.

Crane equipped with lost pressure and zero protection; the driver can make emergency power off in a convenient operation place.

Doors of driver’s cabin and bridge frame has electrical interlock protection device.

In crane legs there has sound and light warning, emergency stop button box and crane rail clamp.

For the crane lifting height exceeds 30m, install anemometer and aviation obstruction lights on the top.

For the wild use crane, with open around and no high-rise buildings, also set up lightning protection device.

For span more than 40m, the crane will be taken synchronized or corrective protective measures.

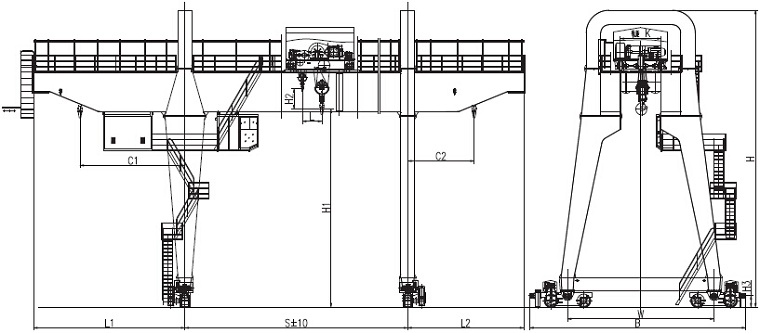

A-type Double Girder Gantry Crane Drawing

Crane technical parameter is an indicator of the operational capability of the crane, its main parameters including: lifting capacity, lifting height, span, working-level, working speed, etc., you can check the general drawing. Various components (such as: reducer, motor, brake, etc.) operation and maintenance, please refer to the manual.

A type double girder gantry crane

Do you have local agent in Myanmar?