Gantry cranes generally work outdoors, and the working environment is relatively poor, so the anticorrosion maintenance of the gantry crane must be done. What are the requirements for the anti-corrosion maintenance of gantry cranes that need to be strictly followed?

Author: dongqicrane

Many customers will directly ask how much the 5 ton single-girder bridge crane is when they call to inquire about the price. We have no way to offer a price directly at this time. The cost of a single girder bridge crane is related to many factors. Span, running distance, and lifting height are all influencing factors.

The installation form of the lifting weight limiter on the electric single beam crane depends on the installation position of the load sensor on the electric hoist. Generally, there are three installation forms of crane limiter on electric single beam crane: fixed pulley type, hook type and wire rope type.

Both the HC type electric hoist and the CD type electric hoist are commonly used lifting equipment, which can be used with single beam cranes. Some friends do not know the difference between these two types of hoists. Today I will briefly introduce them to you.

The lifting mechanism of the gantry crane does not work properly, which may cause problems such as the sliding of the heavy object and the slipping of the hook. When the brake does not work well, check and adjust the brake first.

Some customers need to install explosion-proof overhead cranes (including explosion-proof single-beam overhead cranes and explosion-proof double-beam overhead cranes) because of industry requirements, but they only know that their plant is a Class A plant, and don’t know how many levels of explosion-proof overhead cranes should be installed. Today we will give you a brief introduction.

Infrared travel switch is a safety device commonly used on single-beam cranes, which can control the travel range of single-beam bridge cranes. Today, I will introduce the working principle and adjustment method of the infrared travel switch of the single-beam bridge crane.

After an electric single-beam hosit overhead crane was used for a period of time, it was found that the electric hoist brake of the hoisting mechanism was not very effective. The editor of our factory will explain how to adjust the brake of the electric hoist.

Some customers need to move the single-girder crane used in one workshop to another workshop due to production needs. I don’t know how to move it. I will share with you the next customer’s single-beam crane removal plan and precautions.

Some customers may have I-beam track wear when using electric hoists, mainly due to wear on the side and tread of the I-beam. Today, I will briefly introduce the causes and solutions of electric hoist track wear.

In order to ensure the continuation of production, some operators artificially put the main contactor on top and forcibly connect the main circuit and the control circuit. This approach, although the bridge crane can continue to work, but there will be a big hidden danger.

Have you ever encountered such a problem when using a crane hook: When using it, you will find that the wire rope finds torque, which causes the hook component to rotate. Why does this happen, and how to deal with it?

The single-pole safety sliding line is a kind of power supply sliding line commonly used in overheadcranes, which can be used for electric single-beam cranes and double-beam bridge cranes. The editor briefly introduces the installation method of the single pole slide line.

As a commonly used lifting equipment, the electric single beam crane is a kind of lifting equipment that is used more in the workshop. For most of the production needs of enterprises, it can be said that the production of enterprises is inseparable from single-beam cranes.

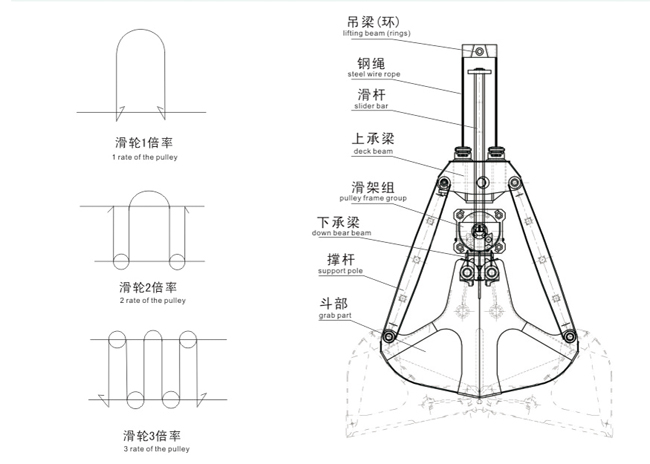

Single-rope grabs mainly rely on the interaction of the sliding blocks, bumps, grooves and thimble of the grab to complete the unloading process. The editor introduces the working principle of the single beam grab.

During crane operation, electric single-beam overhead cranes have to bear various loads (such as static, dynamic, alternating, impact, and vibration, etc.).

KBK flexible track bridge crane originated in Europe. The rigid track bridge crane originated in the United States.

In order to ensure that the European standard single-girder crane can operate efficiently, it needs to spend a lot of maintenance costs to maintain. Let’s check together that 4 ways to reduce the maintenance cost of the European standard single girder crane.