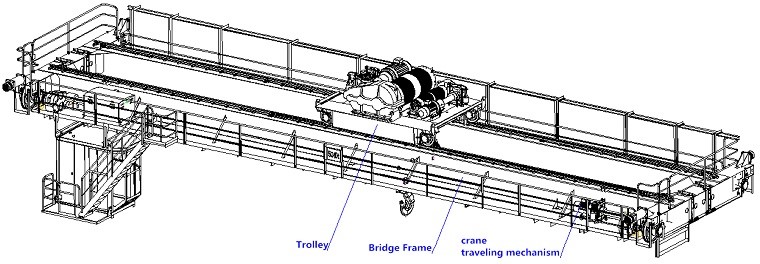

Double Girder Overhead Crane Components and Structure Analysis

As you know, overhead crane includes single girder overhead crane and double girder overhead crane. Double Girder Overhead Crane is double girder bridge crane with hook, suitable for indoor or outdoor fixed cross intercropping handling and transport work. Lifting capacity range is 5T-1000T, working-level generally divided into A3, A5, A6. The work class is Chinese Standard. European standard is 2M, 3M, etc.

A3 overhead crane is apply to maintenance equipment for power plants and other places not often use. A5 double girder overhead crane commonly used in factories and mines, workshops, warehouses and other places. A6 usually used for frequently used places, it belonging to heavy duty system.

Double girder overhead crane is widely-used hoisting machinery at present. It mainly consists of 4 parts, bridge frame (two main girders and two end beams), crane traveling mechanism, trolley with frame and electrical parts. The major supporting frame of the crane is the bridge frame composed by main girder of box shape, end beam, walkway, rail and operating cabinet. Trolley is located on it, trolley is a rigid frame welded by steel plate. Main hoisting mechanism, auxiliary hoisting mechanism and trolley operating mechanism are on the trolley. Crane operating mechanism is equipped on both sides of the bridge frame end beam. The electrical parts are mainly located on the walkway of crane and the operation cabin, and the power is connected to main switch of the crane with special purpose sliding wire.

Trolley and Crane Traveling Mechanism

Trolley and crane operating mechanism are composed of motors, reducers, couplings, brake and wheel set, etc. The wheel runs in two directions driven by reducers and couplings under driving moment generated by motors, trolley and bridge frame can achieve lifting back and forth from place to place.

Lifting Mechanism

Hoisting mechanism is composed of motors, reducers, drum set, wire rope and lifting hook, etc. The lifting hook goes up and down under driving moment generated by motor; the heavy object goes up and down with the hook.

Double girder overhead crane lifting mechanism can be with two trolleys, double trolley generally used for lifting special materials, its structure is safe and reliable, with strong practicability.

Crane trolley consists of one or two sets (main and auxiliary) hoisting mechanism, trolley traveling mechanism and trolley frame, etc.

Operation Mode

Operation mode can be selected for ground operations, remote operation, and driver’s cabin according to the specific circumstances. Because of big span, large lifting capacity, high lifting height, usually more use driver’s cabin operation. Each mechanism of crane operating speed can be designed into fixed speed; may also be designed to VVVF inverter type, using with hook anti-sway.

Security Assurance

In order to ensure normal work and orientation of any position of the crane, safety device are equipped in each mechanism. For example, braking device is equipped on high-speed shaft of motors and reducers, and it’s composed of brakes and braking wheel coupling.

The brake is closed type. Brake shoe is opened when energized, and closed when power off, can make the lifting weight stopped accurately at any position during hoisting, the trolley and crane traveling mechanism will be stopped, and precise orientation will be realized.

Except for braking device, limit switch and overload limiter are equipped on hoisting mechanism. Trolley and crane are all equipped with limit switch. Safety device such as current protection, voltage-loss protection, zero position protection, emergency switch, main isolator, cabin door interlock switch and electric bell prompt etc. are equipped in the electric circuit in order to ensure normal operation of crane and personal safety.

Exposed, rotating parts may have hurt people of the crane, installed with protective cover. Double girder overhead crane Production Process Requirement. The main load components such as main beam, end beam, trolley frame, etc. adopt Q235, Q345 steel material (similar to Fe37 or Fe52). Raw steel material surface shall be shot blasting treated before use.

The main beam and end beam have good stiffness and strength, with box structure, connected by bolts to facilitate transportation. Trolley frame structure is composed of box-beam; the static deflection with full load shall be less than LK/2000, which fully guarantees the smooth operation of mechanism on the trolley. The main beam shall have camber, in the middle camber should be (0.9/1000 ~1.4/1000) S.

External of weld seam shall have no obvious defects, including cracks, cavities, solid inclusions, incomplete fusion and incomplete penetration, shape defects and other defects. And nondestructive testing should be carrying out on weld seams, to ensure that the internal structure of weld seam to meet the requirements.

Wire rope winding on the drum, there shall be at least two safety wraps in addition to the fixed wraps. Width of walkway shall be more than 500mm, walkway applies checker plate and can withstand 3kN movable concentrated load without permanent deformation. Handrail for walkway and end girder shall be 1050mm high, set retaining plate more than 50mm high at the bottom.

Electrics

Crane wires should be laid in slot or metal tube. Wire passing through metal hole to prevent wire wear. Tube or duct should be connected as near to the electrical equipment as possible, wires that can be touched should be laid in duct or metal tube.

Both ends of the wire must have permanent identification mark consistent with that in the circuit or wiring diagram. None of the wire allows middle connection; illuminating wire is allowed to be connected by transition terminal near the equipment. Wires of different mechanisms, different voltage type and different voltage level wires should be kept separately during through the tube. Illuminating wire should be laid separately.

Trolley power supply shall use cable to conduct electricity. Set fixed wire case (box) on suitable position of bridge and trolley frame. And set haulage rope to ensure that cable bears no force during the trolley travels.