Overhead Crane Safety Managing Measures

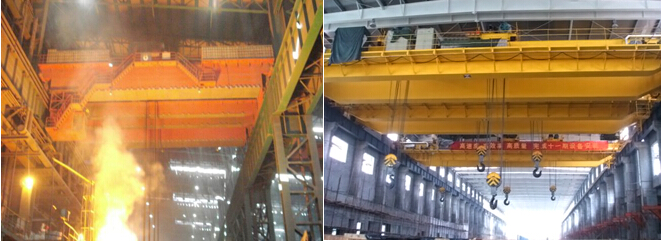

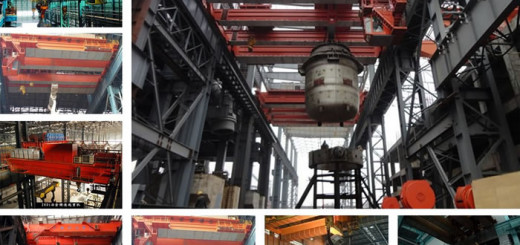

Overhead cranes are widely used in modern factories, and play an important role of improving productive efficiency, reducing labor intensity, and achieving automation and modernization. Shortages in crane management,usage and maintenance decreases accident rates and cause serious economic losses. Extensive use and a significant proportion of overhead cranes in some industries have a direct effect on enterprises’ management and operation. Some following measures can be taken to operate overhead cranes.

Bridge crane operator training

Management system

Various management systems are established and improved, and safety rules and regulations for overhead cranes formulated. Operators should strictly abide by national standards, except lifting equipment and elevators. Other mechanical work should achieve nationwide uniform command signals. Cranes under operation should be overhauled, and if any hidden danger, measures should be taken to eliminate dangers. It is forbidden to use overhead cranes without good maintenance. It bans to take chances and risks. People-oriented,safety-first and prevention-first principle should be really established.

Operation principles

Operational essentials on overhead cranes is“stability, preciseness, swiftness, safety, reason ability”. “stability” refers that the hook and goods are in the needed place without swing and shake. “preciseness” refers to hooks can be stably and precisely in the right place; “swiftness” refers to it that coordinate cooperation of traveling mechanisms can finish lifting with the least time and the shortest distance based in keeping with the principle of stability and preciseness. These four principles are mutually related and inseparable. Without stability and preciseness, there is no swiftness. Without safety, there is no pointing on swiftness. Only pay attention to safety and no swiftness, it can not put into full play efficiency of overhead cranes. Unreasonable operation not only affects both swiftness and service life. Only through stability, preciseness, swiftness and reasonable operation can overhead cranes put into full play the productive role.

Safety education

Such factors as unproper command, lack of experience, uncomprehensive thought, loose fasten or unreasonable operation, absent mindedness, or no eliminated faults and work with sickness all cause personal or mechanical accidents. Therefore, it is critical to have the safety education. There are regular education and pre-work education.

- Regular education

Regular education is that safety and technological department organizes crane operators to learn related safe production knowledge in light of actual circumstances. It is mainly about detailing safety operation rules, learning and exchanging safe production knowledge, summarizing experience and lessons from accident examples of home factor and other factories, and summarizing and popularizing safe production experience of home factory and other factories. - Pre-work education

Pre-work education is that the shift leader, safety officer and shift driver tell about safe production notices to crane operators in few minutes before shift. It mainly includes exchanging safe production experience and lessons of this team and associated teams, pointing out weaknesses of this team, explaining notices and blocking accident holes, and reminding crane operators appropriate use of protective equipment.

These are Overhead Crane Safety Managing Measures, please remember: Safety First!