Single girder overhead crane from DQCRANES | Hoist overhead crane

Single Girder %&&&&&%

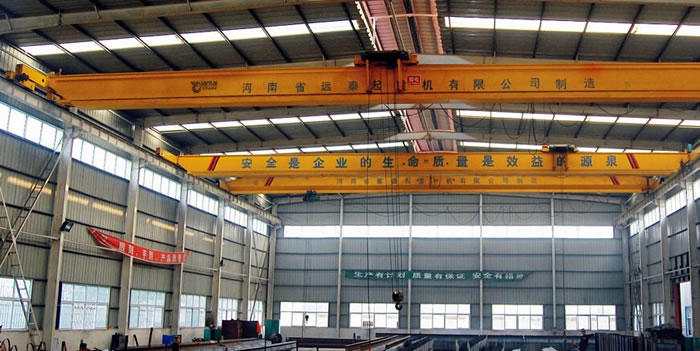

Single girder overhead crane is one kind of light duty and small hoisting machinery. It will improve the effectiveness of your production plant in a very simple way: by maximizing your space.

You can utilize every square inch of your floor space.

- Single girder overhead crane is designed on the basis of LD type hoist crane, characterized by the features of reasonable structure and strong rigidity.

- CD1 and MD1 hoists are used together with this type of crane, a light duty one.

- Lifting capacity ranges from 1ton to 20 ton, with its span from 7.5 to31.5m, work duty from A3 to A5, work temperature from -25 degree to 40 degree.

- It must be handled in a medium without such hazards as combustion, explosion, and erosion

- It is prohibited to be used in the combustible, explosive and corrosive environment!

Single girder overhead crane main types

Single girder bridge crane mainly has three types, customers can choose according to different needs of different types of crane.

Hot sale workshop used single girder overhead crane with electric hoist 1

Single Girder Overhead Crane

LDA model single girder overhead crane

- Capacity: 1ton-20ton

- Span: 7.5-31.5m

- Max. lifting height: 28.5m

- Working duty: A3-A4

- Power supply: 380v-50Hz, 3Phase A.C. or as your request

Hot sale workshop used single girder overhead crane with electric hoist 2

LX Single Girder Overhead Crane

LX model single girder overhead crane

- Capacity: 0.5ton-10ton

- Span: 3m-16m

- Max. lifting height:18m

- Working duty: A3

- Power supply: 380v-50Hz, 3Phase A.C. or as your request

Hot sale workshop used single girder overhead crane with electric hoist 3

LDP Single Girder Overhead Crane

LDP model single girder overhead crane

- Capacity: 3ton-16ton

- Span: 7.5-31.5m

- Max. lifting height: 30m

- Working duty: A3-A5

- Power supply: 380v-50Hz, 3Phase A.C. or as your request

The crane girder is of welded girder construction. This result in lower dead weight with a high degree of vertical and horizontal rigidity and small wheel loads being transmitted to the crane runway.

Control method: Pendent line with press button or remote control or both

Painting: Primer and finishing paint

Color: According to your demand

Average thickness: About 100 microns

Single girder overhead crane Safety Feature

Safety is the most important issue for crane. To ensure the safety, the following safety devices are equipped in DONGQICRANE.

- Crane traveling limit switch

- Weight overload protection device

- Lifting height limit device

- Voltage lower protection function

- Phase sequence protection function

- Emergency stop function

- Rain cover for outside hoist, driving units, electrical cubicle.

- Warning indicator: flashing lights and warning sound.

- Wireless infra-detector for anti-collusion

Single girder overhead crane main parts

Single Girder Overhead Crane Parts

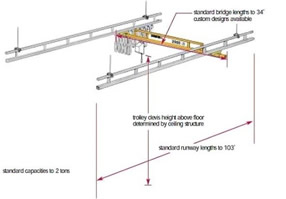

- Main beam – The main traveling structure of the crane which spans the width of the bay and travels in a direction parallel to the runway. The bridge consists of two end trucks and one or two bridge girders depending on the equipment type. The bridge also supports the trolley and hoisting mechanism for up and down lifting of load.

- End trucks – Located on either side of the bridge, the end trucks house the wheels on which the entire crane travels. It is an assembly consisting of structural members, wheels, bearings, axles, etc., which supports the bridge girder(s) or the trolley cross member(s).

- Bridge Girder(s) – The principal horizontal beam of the crane bridge which supports the trolley and is supported by the end trucks.

- Runway – The rails, beams, brackets and framework on which the crane operates.

- Runway Rail – The rail supported by the runway beams on which the crane travels.

- Hoist – The hoist mechanism is a unit consisting of a motor drive, coupling, brakes, gearing, drum, ropes, and load block designed to raise, hold and lower the maximum rated load. Hoist mechanism is mounted to the trolley.

- Trolley – The unit carrying the hoisting mechanism which travels on the bridge rails in a direction at right angles to the crane runway. Trolley frame is the basic structure of the trolley on which are mounted the hoisting and traversing mechanisms.

- Bumper (Buffer) – An energy absorbing device for reducing impact when a moving crane or trolley reaches the end of its permitted travel, or when two moving cranes or trolleys come into contact. This device may be attached to the bridge, trolley or runway stop.

Single girder overhead crane Packing

- Electric parts are packed by high quality plywood crate to reduce distortion in conveying;

- Main beams, end beams and electric hoist or winch are packed by plastic woven cloth. It can reduce abrasion when transport.

Single Girder Overhead Crane Packing

Single girder overhead crane Delivery

- If the size of whole crane are suitable for container ship, usually by container;

- If the size is too big, usually by bulk ship or by container after truncation;

- Transport ways are based on reducing cost for you and keep the crane in good condition.

Overhead crane services of DQCRANES

Dongqi can provide overall overhead crane services for all types of industries overhead cranes, and the main services are as follow:

|

Crane project design Cranes designed by DQCRANES will solve any of your crane problems and material handling problems without spending any unnecessary expenditures. |

|

Crane Installation EASAY installation, wonderful working performance. DQCRANES can provide on-site crane installation services and our crane engineers will be at your services when necessary. |

|

Lifetime Maintenance Crane maintenance from DQCRANES ensures your safety and working efficiency. |

|

Crane operator Training DQCRANES training includes crane operation, maintenance and inspection, and crane spare parts, etc. |

|

Technical support The powerful technical support of DQCRANES will solve your crane technical problems. |

|

Crane parts DQCRANES parts will renew your cranes. |

Overhead crane Manufacturer Contact

Address: No.1, Weier Road, Henan (Changyuan) Crane Industry Park, China.

Sales Tel: +0086-371-86687182

Fax: +0086-371-86687182

Skype: cranes.dongqi

Email: [email protected]