Ellsen 5 Ton Overhead Crane Write Your Demand Now As a type of small and light overhead crane, 5 ton bridge crane usually is used in warehouse, factory and store shop to lift, move or transport all kinds of materials. The key feature of 5 ton bridge crane is its compact structure, which makes the overhead crane handle easily, and every part of overhead crane can work together very well. Best meet the need of high safety and productivity in modern warehouse. Therefore, 5 ton bridge crane is adjustable, and can fit various different working environments.

Tagged: Gantry Crane

Get Free QuoteEOT crane stands for electric overhead traveling crane, which is designed to move, lift or transport materials up to 5000kg. The big lifting capacity makes the EOT crane as the ideal solution for particular demanding task. The electric overhead traveling crane can be divided into five different sections, such as the bridge girders, end carriages, hoisting trolley also called crab, the long travel machinery, and floor operation. There are several different designs about EOT crane. Single girder overhead traveling cranes, double girder overhead traveling crane, under running overhead traveling and wall traveling cranes.

Material handling overhead crane, a type of bridge crane, plays an important role on movement, storage, control, protecting materials, goods and products. A material handling overhead crane usually is used to lift and transfer heavy material, which can avoid unnecessary strain of workers. Therefore, a material handling overhead crane doesn’t only serve as a crane equipment to lift and load goods, it also helps to prevent clients from injures during the working process.

As the best solution, industrial crane can adapt various working environments including hazardous and poor conditions. In other world, industrial crane is ideal to improve the working efficiency and productivity. Due to high safety and large lifting capacity, the industrial overhead crane is widely used in workshop, warehouse, power station, metallurgical mills and other place.

Ellsen Magnetic Overhead Crane Send Your Demands NowThe magnetic overhead crane produced by Ellsen Machinery Equipment Co., Ltd is a special product mainly used to lift iron, steel or cylinder and so on. General, magnetic bridge cranes are equipped with magnetic chunk to ensure it works well. An overhead magnetic crane can divide into four parts including crane walking structure, motor trolley, magnetic chunk and electric drive equipment. Bridge magnet Crane will be the best choice for steel factory, warehouse, transport and harbor.

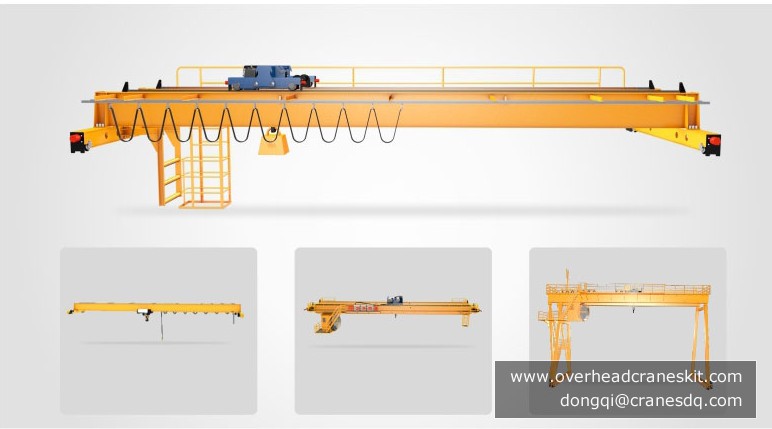

As a type of crane, gantry overhead crane is similar with overhead crane, except the gantry structure. The support structure of overhead crane is usually fixed in some sites, like a wall or ceiling of a building. While a gantry crane uses the leg with wheel to support. The lifting capacity of overhead gantry crane is flexible and adjustable, which with a wide range from smallest to heaviest in the world.

As a system of overhead crane, overhead shop crane is designed to use in non-industrial applications, such as the garage, pole barn, workshop and man cave. The overhead shop crane can help workers made a job done faster and safer. As well as aoverhead shop crane system can lift the materials more than people can handle by hand, which maximum increases the work effectively and productivity.

As a main type of overhead crane, single girder overhead crane is ideal solution for lift, move or transport materials. Commonly, single girder bridge crane is regarded as a kind of light duty lifting equipment match with CD1, MD1 type electric hoist. In order to best meet the demands of productivity and safety, the single beam bridge crane is widely used in workshop, warehouse, and yard.

Gantry cranes lift heavy objects, particularly in the construction and shipbuilding industries. Different types of gantry cranes are used for various purposes. Gantry cranes lift objects using a hoist that fits on a horizontal beam or girder and moves horizontally. Two support pillars support the beam, and the hoist carries objects from one point to another overhead. Gantry cranes have powered rails at the bottom or wheels that can move the crane to different locations.

A gantry crane is a structure that has at least two legs that support a bridge or beam. The device allows you to move loads from one location to another. You see larger gantry cranes along shipyards or train stockyards. The crane will lift a load and move it horizontally to a desired location. You can build one of these devices to use in your workshop or garage to lift loads, such as engines, logs or other articles that are too heavy to lift manually. With a little welding knowledge and some mechanical aptitude, you can build a gantry crane.

Score Group plc operates worldwide providing engineering services across five continents within a range of sectors which include oil & gas, nuclear and marine. The Score Group of companies primarily...

Chain Electric Hoist is European FEM and DIN standard electric hoist, with modular, maintenance-free design, easy installation, flexible operation, compact structure and reliable performance.

DH Electric Hoist adopt European FEM standard, modular design for easy assembly, replacement and maintenance, with strong stability, high safety factor, long service life.

Metallurgical Electric Hoist is lifting equipment used in metallurgy environment for lifting and handling molten metal, it is improved product on the basis of CD, MD electric hoist, with dual brake, double spacing, insulation boards and other varieties of protections, working level is M6. It is safe, reliable, parts with high degree of universality and compact structure.

Explosion-proof Electric Hoist can be used alone or supporting the use of single girder, electric hoist double girder, electric hoist gantry crane , jib crane and other explosion-type girder, explosion-proof grade ExdⅡBT4 and ExdⅡCT4, widely used in factories with flammable gas, dust and air formation of explosive gas mixtures, combustible dust atmosphere and other places. With strong stability, high safety factor, long mechanical service life, modular design, simple structure and balanced design, etc.

OverviewDemag Electric Hoist is designed on the basis of advanced electric hoist, with high degree of intelligence. It is with advantages such as light weight, low height, sophisticated configuration, high transmission efficiency, low noise, energy saving and environmental protection, etc. Demag Electric Hoist adopts modular design, with high degree of universalization of all parts, high maintenance-free rate, less wearing parts.

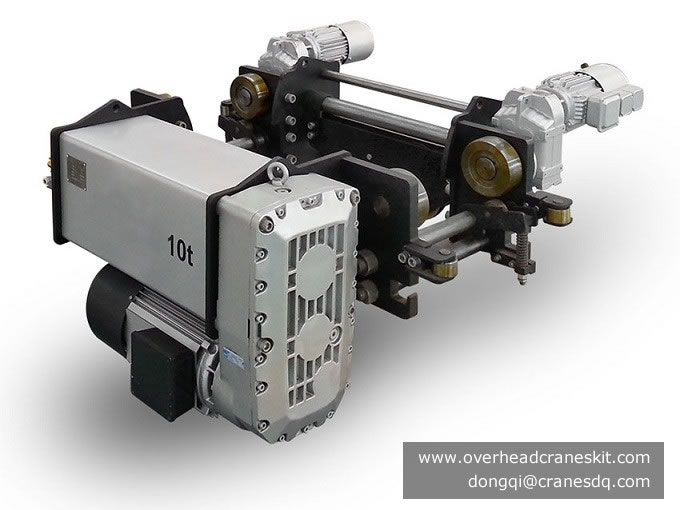

MD-type wire rope hoist is two-speed electric hoist compared to CD electric hoist , there are fast and slow speed, especially for fine handling working places. With the advantages of extensive use, compact structure, design and manufacture size equalization, parts versatility, easy operation, etc. it can be not only installed separately on I-steel beam, but also can be installed in single-beam, double-beam, cantilever and gantry cranes.

CD-type wire rope electric hoist used separately or in combination with single beam, hoist double girder crane, gantry crane, cantilever crane and others, widely used in railways, docks, industrial and mining enterprises, warehouses and other places for lifting heavy objects.