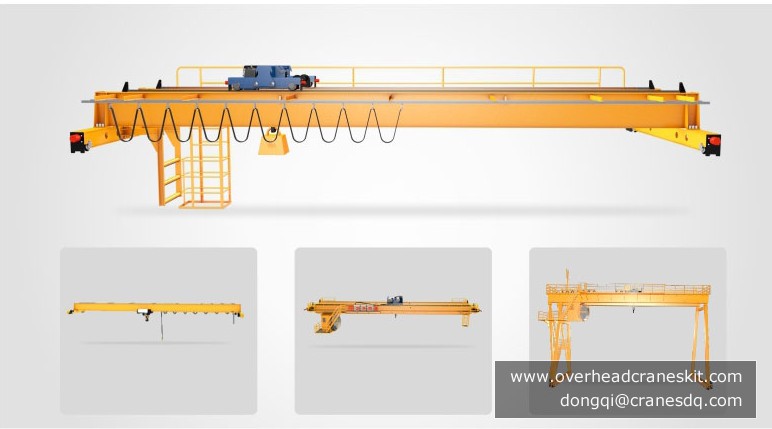

Get Free QuoteEOT crane stands for electric overhead traveling crane, which is designed to move, lift or transport materials up to 5000kg. The big lifting capacity makes the EOT crane as the ideal solution for particular demanding task. The electric overhead traveling crane can be divided into five different sections, such as the bridge girders, end carriages, hoisting trolley also called crab, the long travel machinery, and floor operation. There are several different designs about EOT crane. Single girder overhead traveling cranes, double girder overhead traveling crane, under running overhead traveling and wall traveling cranes.

Tagged: overhead crane

Indoor crane provides a new solution for load and transport of goods or something else in a confined warehouse or workshop, which combining lifting with drive platform creatively, reducing the costs and complexity of indoor loads efficiently.

Light duty overhead crane is a type of bridge crane with litter lifting capacity. However, compared with heavy duty overhead crane, a light duty crane can overcome fast delivery, quick and easy installation. At the same time, a light duty overhead crane will reduces your spending budget and save your factory space.

Material handling overhead crane, a type of bridge crane, plays an important role on movement, storage, control, protecting materials, goods and products. A material handling overhead crane usually is used to lift and transfer heavy material, which can avoid unnecessary strain of workers. Therefore, a material handling overhead crane doesn’t only serve as a crane equipment to lift and load goods, it also helps to prevent clients from injures during the working process.

As the best solution, industrial crane can adapt various working environments including hazardous and poor conditions. In other world, industrial crane is ideal to improve the working efficiency and productivity. Due to high safety and large lifting capacity, the industrial overhead crane is widely used in workshop, warehouse, power station, metallurgical mills and other place.

Ellsen Magnetic Overhead Crane Send Your Demands NowThe magnetic overhead crane produced by Ellsen Machinery Equipment Co., Ltd is a special product mainly used to lift iron, steel or cylinder and so on. General, magnetic bridge cranes are equipped with magnetic chunk to ensure it works well. An overhead magnetic crane can divide into four parts including crane walking structure, motor trolley, magnetic chunk and electric drive equipment. Bridge magnet Crane will be the best choice for steel factory, warehouse, transport and harbor.

As a type of crane, gantry overhead crane is similar with overhead crane, except the gantry structure. The support structure of overhead crane is usually fixed in some sites, like a wall or ceiling of a building. While a gantry crane uses the leg with wheel to support. The lifting capacity of overhead gantry crane is flexible and adjustable, which with a wide range from smallest to heaviest in the world.

Portable overhead crane, also be called mobile bridge crane, which is adjustable and movable. A portable overhead crane is made up of two main organizations, one is the power plant, and the other is the support structure. Portable overhead crane is a new type of lifting machine with the advantages of small volume, light weight and easy operation. And therefore mobile overhead crane is widely used in factory, workshop, warehouse, and logistic to lift, move or load materials.

As a system of overhead crane, overhead shop crane is designed to use in non-industrial applications, such as the garage, pole barn, workshop and man cave. The overhead shop crane can help workers made a job done faster and safer. As well as aoverhead shop crane system can lift the materials more than people can handle by hand, which maximum increases the work effectively and productivity.

Remote control overhead crane belongs to the overhead crane, which using the remote control when operate the crane. There are three different modes of crane’s manipulation. The wireless remote control, radio remote control and the cabin control. While remote control overhead crane is highly adaptable and strong practical. Overhead crane radio remote control can be divided into distinct types according to accessory, working level and working environment. Aimed to girder, there are single overhead crane and double bridge crane. In term of working level, you can consider the light duty overhead crane and the heavy duty crane. Regarding several special working environment, the explosion-proof overhead crane and electromagnetic overhead crane can best meet your demand.

As a particular type of overhead crane, the explosion-proof overhead crane we produced is qualified for various dangerous and hostile working conditions, which contains workshop of metallurgical mills, petrochemical plant, natural gas fired power plant and paint shop. All our rich experience and advanced technology are built into every overhead crane equipment or component. We produce each lifting device all on the basis of international standard and regulations.

50 ton overhead crane is a type of bridge crane. Because of high working duty and big working capacity, 50 ton bridge crane is widely used in industrial and mining enterprises, steel industry, chemical industry, railway traffic and port or pier. Overhead crane 50 ton is also called heavy duty overhead crane, can be used in several complex and poor environment. 50 ton bridge crane plays a very important role in the warehouse or factory, which can increase productivity effectively and maximum save spending.

As a type of bridge crane, overhead traveling crane is designed to lift, move or transport materials up to 120 tons. Because of the great spans and big lifting capacity, an overhead traveling crane is the ideal solution for particularly demanding tasks. According to the different ways of manipulation, the traveling overhead cranes can be divided into manual overhead traveling crane and electric overhead traveling crane. And an electric overhead traveling is made up of five parts. The bridge girders, end carriages, hoisting trolley also called crab, long travel machinery and cabin. Due to best meet the requirements of high safety and productivity, the traveling overhead crane is widely used in factory, warehouse, workshop and other place.

10 ton overhead crane is a kind of bridge crane, which can meet the need of productivity and safety perfectly in factory, warehouse, and port or stuff yard. Because high working duty and best stability, overhead crane 10 ton provide so much convenient for moving, lifting and transmitting goods or other materials.

As a main type of overhead crane, single girder overhead crane is ideal solution for lift, move or transport materials. Commonly, single girder bridge crane is regarded as a kind of light duty lifting equipment match with CD1, MD1 type electric hoist. In order to best meet the demands of productivity and safety, the single beam bridge crane is widely used in workshop, warehouse, and yard.

Dongqi 2 Ton Bridge Crane Leaves Your Demands Now2 ton bridge crane is a type of overhead crane, can be classified into portable or mobile bridge crane. As a light weight bridge crane, 2 ton bridge crane is widely used in factory, coal mine, harbor, warehouse and workshop to lift, move or load materials. A 2 ton bridge crane can best meet the requirements of high-safety and productivity in factories.

Under hung bridge crane, also called under slung bridge crane or under running bridge crane, which are designed for flexibility and functionality. Because the under hung system is usually lighter than top running system, so a under hung overhead crane can be hung in the building structure directly without support. Compared with top running bridge crane, under hung overhead crane is more suitable for factory that height is limited.

Differ with under hung bridge crane; top running overhead crane is designed to lift massive loads. Generally, a top-running system is much heavier than under hung equipment. For top-running systems, the end trucks are supported on rails, which are attached to the top of the crane runway. Besides, as the best and efficient lifting solution in large coverage facility, top running overhead crane or bridge crane can be designed in both single girder, double or box girder, there are enough options to suit your demands.