Warehouse overhead crane is a kind of overhead crane, which mainly be made to adapt various types of warehouse. Using a warehouse overhead crane, commodities or material substance will be moved or lifted easily. Overhead crane for warehouse can be divided into different modes. In the light of girder, warehouse bridge crane can divide into singer girder overhead crane and double girder overhead crane. While on the basis of work duty, a warehouse bridge crane contains light-duty overhead cranes and heavy-duty bridge crane. There are two distinct control forms supplied for the warehouse overhead crane, one is ground control with a rope handle, another is the remote control. A customized crane also would be produced by our company on the basis of clear requirements.

Tagged: overhead crane

The small overhead crane usually has one hoisting appliance; it makes single movement of materials need to lift. Due to compact structure and simple operation, small bridge crane commonly used in workshop, warehouse, dock storage and other place. There are various kinds of small bridge crane, such as wheel jack, manual or electric hoist, single girder overhead crane and all kinds of winches. Additional, our company also can custom crane to meet all your requirements.

Some states require certification and/or licensing to operate a crane, while others such as Virginia have yet to enact such regulation. Setting aside the regulation, gaining crane-operator certification form the National Commission for the Certification of Crane Operators (NCCCO), located in Fairfax, Va., can boost employers’ confidence levels when making hiring decisions. Certification helps employers ascertain your knowledge and expertise in operating a crane system, as well as gauge your commitment to safety on the job.

Construction and manufacturing companies commonly use overhead cranes in their operations to transport materials. While useful, they also introduce potentially grave dangers. Each year, overhead crane accidents cause severe injuries or deaths. To prevent disasters, recognize specific hazards that occur during use and follow the safety guidelines and procedures to avoid them.

Overhead cranes come in many forms. The crane can run on rails, gantries or just hang on a beam attached to a wall. Cranes can be controlled by an attached handset, from a cab or by a remote control device. No matter what style of crane, the operator must inspect it before use.

According to the Associated General Contractors of America, there are an average of 22 deaths each year related to crane operation. In response to this statistic, in August, 2010, the Occupational Safety and Health Administration adopted regulations that all overhead crane operators be qualified and certified. Section 1926.1427 of the U.S. Department of Labor (Federal Register), Cranes and Derricks in Construction Final Rule outlines the requirements for training to receive either certification or qualification.

The National Commission for the Certification of Crane Operators (NCCCO) developed and manages certification for crane operators. Each state has individual laws, but most require certification through the NCCCO. In order to become certified, you must pass a two-part exam, consisting of a written and a practical portion. These two portions are administered independently and you pay testing fees for each of them separately.

The first step to becoming a crane operator is to obtain a high school diploma or equivalent. According to the U.S. Bureau of Labor Statistics, aspiring crane operators and excavating machine operators also need several years of experience in related jobs before they become full-time crane operators. New operators must undergo on-the-job training from a senior worker for an amount of time determined by the employer.

An overhead crane, commonly called a bridge crane, is a type of lifting crane found in industrial environments. An overhead crane consists of parallel runways with a traveling bridge spanning...

What’s your impression to Chinese products? What’s your impression towards products with the label of “Made in China”? For lots of customers overseas, they always considered Chinese hoist and crane...

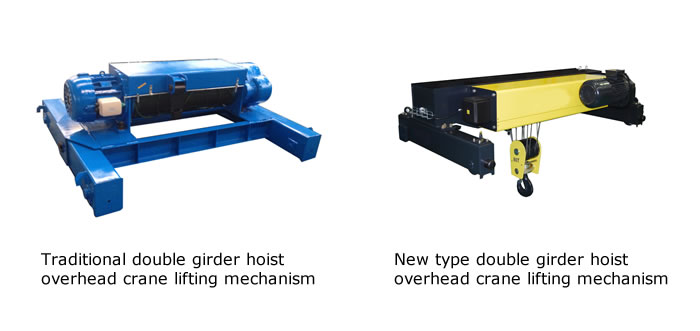

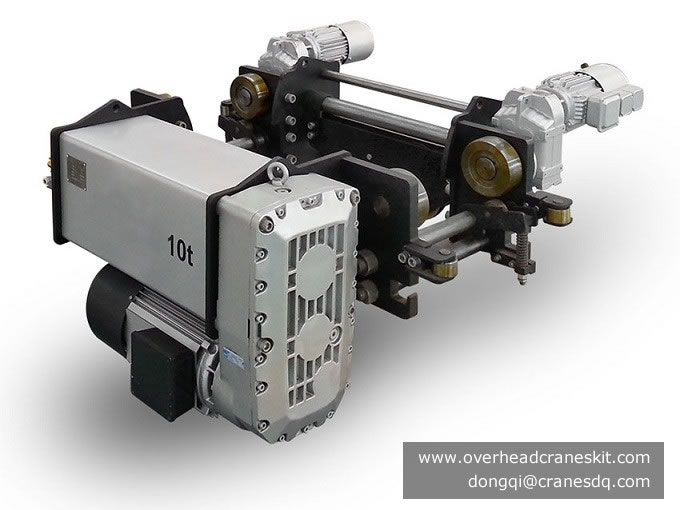

Overview This article mainly analyzes the differences between trolley overhead crane and hoist double girder overhead crane in formal structure, and also examining the weaknesses and lack of imported brands...

Chain Electric Hoist is European FEM and DIN standard electric hoist, with modular, maintenance-free design, easy installation, flexible operation, compact structure and reliable performance.

DH Electric Hoist adopt European FEM standard, modular design for easy assembly, replacement and maintenance, with strong stability, high safety factor, long service life.

Metallurgical Electric Hoist is lifting equipment used in metallurgy environment for lifting and handling molten metal, it is improved product on the basis of CD, MD electric hoist, with dual brake, double spacing, insulation boards and other varieties of protections, working level is M6. It is safe, reliable, parts with high degree of universality and compact structure.

Explosion-proof Electric Hoist can be used alone or supporting the use of single girder, electric hoist double girder, electric hoist gantry crane , jib crane and other explosion-type girder, explosion-proof grade ExdⅡBT4 and ExdⅡCT4, widely used in factories with flammable gas, dust and air formation of explosive gas mixtures, combustible dust atmosphere and other places. With strong stability, high safety factor, long mechanical service life, modular design, simple structure and balanced design, etc.

OverviewDemag Electric Hoist is designed on the basis of advanced electric hoist, with high degree of intelligence. It is with advantages such as light weight, low height, sophisticated configuration, high transmission efficiency, low noise, energy saving and environmental protection, etc. Demag Electric Hoist adopts modular design, with high degree of universalization of all parts, high maintenance-free rate, less wearing parts.

MD-type wire rope hoist is two-speed electric hoist compared to CD electric hoist , there are fast and slow speed, especially for fine handling working places. With the advantages of extensive use, compact structure, design and manufacture size equalization, parts versatility, easy operation, etc. it can be not only installed separately on I-steel beam, but also can be installed in single-beam, double-beam, cantilever and gantry cranes.

CD-type wire rope electric hoist used separately or in combination with single beam, hoist double girder crane, gantry crane, cantilever crane and others, widely used in railways, docks, industrial and mining enterprises, warehouses and other places for lifting heavy objects.